At Icon Metalcraft, Inc., we address all aspects of product engineering to promote the functionality and manufacturing feasibility of your products. We have more than 80 years of combined experience in mechanical engineering and by tapping into our expertise; we provide an extra measure of value from initial concept through mechanical analysis, prototyping, and fabrication. Our process involves a thorough engineering review of your drawings and specifications followed by preparation of an efficient production plan that incorporates all required manufacturing and fabrication processes.

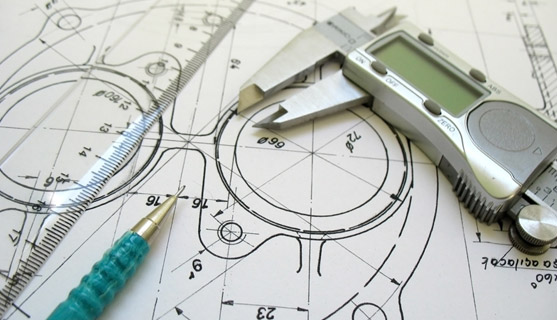

By taking a tactical approach to evaluating the mechanical architecture and dimensional aspects of your product, we develop practical yet innovative solutions to ensure quality and low-cost manufacturing. We use the latest versions of (CAD) and computer-aided engineering (CAE) tools to verify, create 3D layouts, evaluate raw materials, and perform structural and other analyses. Along with tool and die, we also engineer production fixtures to facilitate fabrication, testing, and assembly. Our manufacturing plans include detailed routing and scheduling to ensure efficient and timely movement of product through the entire production cycle.

We are ISO 9001:2015 and AS 9100D certified and have extensive experience with companies in the aerospace and defense industry. Other markets served include biotech, electronics, machinery manufacturing, electronics, and much more. Our past experience includes intelligent solutions for products as diverse as medical devices, custom test equipment and instrumentation, refrigeration equipment, satellite components, robotics, wireless communication devices, and a long list of others. To learn more about our engineering capabilities contact us directly. We welcome the opportunity to discuss your project.